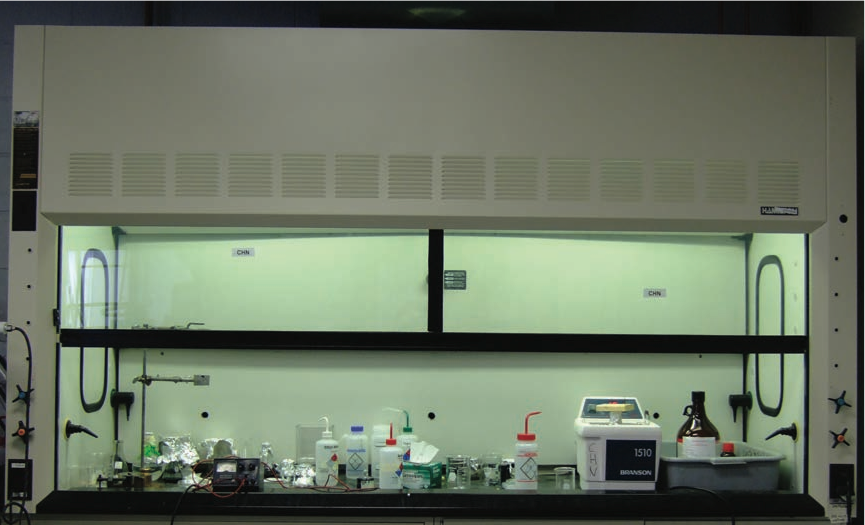

Laboratory fume hoods are a piece of equipment required for the safety of laboratory operatives. Without these hoods, workers would be exposed to dangerous and hazardous fumes. They work by ensuring air remains in the fume hood, away from those who are working on experiments in a laboratory. In the past, lab fume hoods were made from wood, but new advances in technology have changed this. Today, therefore, they are usually made using a mild steel that is epoxy-coated. Thanks to these changes in design, the safety of laboratories has been massively increased.

Why Are Fume Hoods Needed?

Obviously, when experimenting with different products for research or testing in a laboratory, fumes and other hazardous chemicals will be released. Hence, fume hoods are essential to make sure operatives involved in the experiments, or otherwise present in the lab, have to be fully protected. Generally speaking, these hoods are found in industrial locations where dusts, vapors, and gases are released.

Two different types of fume hoods exist, being the ducted and the recirculating fume hood. Both have pretty similar processes, although there are a few key differences between them as well. In recirculating designs, air around a test is drawn into the filter, which should be a HEPA filter, after which pure air is discharged back into the cabinet or the laboratory. In ducted models, the air is drawn into it and then goes into a purpose-built ventilation system. This system then purifies the air and releases it back outside. Often, these vent systems have multiple fume hoods attached to it.

Fume Hood Guidelines

All laboratory equipment has to be meet certain set guidelines in order to function properly. These rules are in place to make sure people are safe and protected at all times. However, it is equally important that operatives are properly trained on the substances they are using, so that they know what the particular chemicals’ toxic properties are. Some, for instance, are over-explosive, which means additional precautions have to be taken as well.

Fume hoods should not be operated unless they clear indicate that they are not opening. Additionally, operators should regularly check the magenhelic reading on the fume hood, comparing this to the reading that has to be listed on the inspection sticker place on the hood. If there is a difference between those two readings, there is reason to believe that there is something wrong with the hood and that it isn’t operating as it should.

Last but not least, operatives must at all times wear safety glasses and gloves, and they must be committed to keeping their work areas clean. Any chemical residues left on the hood chamber have to be removed once work has been completed. Being safe when working with hazardous materials, in other words, is down to two things: having the right equipment in place, and ensuring people follow the appropriate working practices. Without those two key elements, there is a significant danger to overall health.